The Ultimate Guide to Inventory Management in Dubai & UAE for 2025

Introduction: The Pulse of Your Business – Inventory Management

In the dynamic and competitive business landscape of Dubai and the UAE, efficient inventory management is no longer a back-office function; it’s the very pulse of your business. It dictates your ability to meet customer demands, optimize costs, and maintain a healthy bottom line. Whether you’re a burgeoning e-commerce startup in Sharjah, a bustling retail giant in Dubai, or a manufacturing powerhouse in Abu Dhabi, mastering inventory management is paramount to sustained success. For many businesses in this region, implementing a comprehensive system like Microsoft Dynamics 365 Business Central has become a key strategy.

But what exactly is inventory management, and why has it become so critical?

What is Inventory Management?

At its core, inventory management is the systematic process of overseeing the flow of goods – from procurement to storage and finally, to sale or usage. It encompasses a wide range of activities, including:

- Stock Control: Tracking the quantity of each item in your inventory, knowing what you have, where it is, and its value.

- Demand Forecasting: Predicting future demand to ensure you have enough stock to meet customer needs without overstocking.

- Ordering and Procurement: Efficiently placing purchase orders with suppliers, negotiating favorable terms, and managing lead times.

- Warehouse Management: Optimizing storage space, organizing inventory for easy access, and streamlining warehouse operations.

- Inventory Optimization: Balancing inventory levels to minimize holding costs while ensuring sufficient stock to meet demand.

- Reporting and Analysis: Generating insightful reports on inventory levels, stock movements, sales trends, and key performance indicators (KPIs) to inform decision-making.

In essence, inventory management is about having the right products, in the right quantities, at the right place, and at the right time – all while minimizing costs and maximizing efficiency. It’s a delicate balancing act that requires careful planning, execution, and continuous optimization.

Why is Inventory Management Crucial in Today’s Business Landscape?

In today’s fast-paced, interconnected, and customer-centric world, effective inventory management is no longer optional – it’s a necessity. Here’s why:

- Meeting Customer Expectations: Customers today expect instant gratification. They want products to be readily available and delivered quickly. Efficient inventory management ensures you can fulfill orders promptly, leading to higher customer satisfaction and loyalty.

- Optimizing Costs and Profitability: Poor inventory management can lead to significant financial losses. Overstocking ties up capital in unsold goods, increases storage costs, and risks obsolescence. Stockouts, on the other hand, result in lost sales, dissatisfied customers, and potential damage to your brand reputation. Effective inventory management helps you strike the right balance, minimizing costs and maximizing profitability.

- Streamlining Operations and Boosting Efficiency: Manual inventory management processes are time-consuming, error-prone, and inefficient. An optimized inventory management system automates many tasks, freeing up valuable time for your team to focus on strategic initiatives and core business activities.

- Gaining a Competitive Edge: In a competitive market like Dubai and the UAE, businesses that excel at inventory management gain a significant advantage. They can respond quickly to market changes, offer better service, and operate more efficiently than their competitors.

- Data-Driven Decision Making: Modern inventory management systems provide real-time data and insightful reports, empowering businesses to make informed decisions about purchasing, pricing, marketing, and overall business strategy.

Who Needs an Inventory Management System in Dubai & UAE?

The short answer? Almost every business in Dubai and the UAE can benefit from an effective inventory management system. Whether you are:

- Retail Businesses: From fashion boutiques in Dubai Mall to electronics stores in Deira, retailers need to manage diverse product ranges and fluctuating customer demand.

- E-commerce Companies: Online businesses in the UAE rely heavily on efficient warehousing and order fulfillment, making inventory management critical for success.

- Manufacturing Companies: Manufacturers in Jebel Ali Free Zone and other industrial areas require robust systems to manage raw materials, work-in-progress, and finished goods.

- Wholesale and Distribution Businesses: Distributors across the UAE need to track large volumes of inventory moving through multiple locations.

- Food and Beverage Businesses: Restaurants, cafes, and food suppliers in Dubai must manage perishable goods and ensure freshness, making inventory control essential.

- Healthcare Providers: Hospitals and clinics in the UAE need to manage medical supplies, pharmaceuticals, and equipment efficiently.

- Small and Medium-Sized Enterprises (SMEs): Growing SMEs in Dubai and the UAE often outgrow manual inventory processes and need scalable solutions to support their expansion.

- Large Enterprises: Multinational corporations with operations in the UAE require sophisticated, enterprise-grade inventory management systems to handle complex global supply chains.

No matter your industry or size, if your business deals with physical goods, mastering inventory management is crucial for achieving operational excellence and sustainable growth in the competitive Dubai and UAE markets.

Decoding the ‘What’: Understanding Inventory Management Systems (IMS)

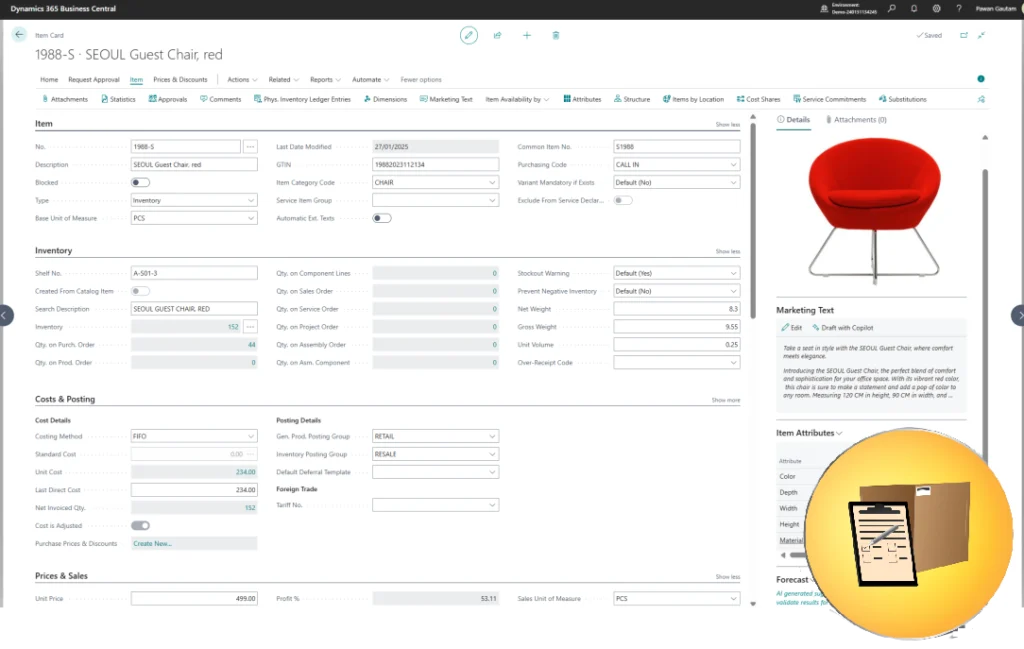

Now that we’ve established the critical importance of inventory management, let’s delve deeper into the systems that make it all possible. An Inventory Management System (IMS) is more than just software; it’s a holistic approach encompassing software, tools, and well-defined processes designed to streamline and optimize your inventory operations. Many businesses find that integrated ERP systems, such as Microsoft Dynamics 365 Business Central, offer comprehensive IMS capabilities alongside other crucial business functions.

Defining an Inventory Management System

An Inventory Management System (IMS) is a comprehensive solution that integrates various components to provide businesses with real-time visibility and control over their stock. It typically includes:

- Software: The central component, providing a platform for tracking inventory, managing orders, generating reports, and automating tasks. This software can range from basic spreadsheets to sophisticated cloud-based ERP systems.

- Hardware: Optional but often beneficial, hardware components can include barcode scanners, RFID readers, mobile devices, and specialized warehouse equipment to enhance data capture and operational efficiency.

- Processes: Well-defined workflows and procedures for receiving goods, putaway, picking, packing, shipping, stocktaking, and reporting. These processes ensure consistency and accuracy in inventory operations.

- People: Trained personnel who understand inventory management principles and are proficient in using the IMS software and hardware. Their expertise is crucial for effective system implementation and ongoing management.

Core Objectives of an IMS

The primary objectives of implementing an Inventory Management System are to:

- Enhance Operational Efficiency: Automate manual tasks, streamline workflows, and improve overall productivity in inventory-related operations.

- Reduce Inventory Costs: Minimize holding costs associated with excess stock, prevent stockouts and lost sales, and optimize ordering processes to secure the best possible prices.

- Improve Inventory Accuracy: Reduce errors in stock counts, track inventory movements in real-time, and ensure data integrity for reliable reporting and decision-making.

- Boost Customer Satisfaction: Ensure timely order fulfillment, minimize delays caused by stockouts, and provide accurate information to customers regarding product availability.

- Optimize Warehouse Management: Improve space utilization, streamline picking and packing processes, and enhance overall warehouse efficiency.

- Enable Data-Driven Decision Making: Provide real-time insights into inventory levels, sales trends, and performance metrics to support informed business decisions.

Key Components of an IMS

A robust Inventory Management System typically comprises several key components working in synergy:

- Inventory Tracking: The foundation of any IMS, this component provides real-time visibility into stock levels across all locations, tracking item quantities, locations, and movements.

- Reporting and Analytics: Generates comprehensive reports on inventory levels, stock valuation, sales trends, order history, and other key metrics, providing insights for informed decision-making.

- Demand Forecasting: Utilizes historical data and algorithms to predict future demand, helping businesses optimize stock levels and prevent both overstocking and stockouts.

- Inventory Alerts and Notifications: Automated alerts trigger notifications when stock levels fall below predefined thresholds, prompting timely reordering and preventing potential stockouts.

- Purchase Order Management: Streamlines the purchasing process, from creating and sending purchase orders to tracking vendor performance and managing invoices.

- Sales Order Management: Integrates with sales processes, automatically updating inventory levels upon order placement and fulfillment, ensuring accurate stock visibility.

- Warehouse Management Features: May include features for optimizing warehouse layout, managing picking and packing processes, and tracking inventory within the warehouse.

- Integration Capabilities: Seamlessly integrates with other business systems such as CRM, POS, accounting software, and e-commerce platforms, creating a unified business management ecosystem.

By understanding these core objectives and key components, businesses in Dubai and the UAE can better appreciate the power of an Inventory Management System and its potential to transform their operations.

![]()

The ‘Why’ Unveiled: Benefits of a Robust Inventory Management System

Implementing a robust Inventory Management System is not just about adopting new software; it’s about unlocking a wealth of benefits that can significantly impact your bottom line and drive business growth in Dubai and the UAE. Let’s explore the key advantages:

Enhanced Efficiency and Productivity

- Automation of Manual Tasks: Say goodbye to tedious manual stock counts, data entry errors, and time-consuming spreadsheet updates. An IMS automates these routine tasks, freeing up your team to focus on more strategic activities. Solutions like Microsoft Dynamics 365 Business Central excel in automating these processes.

- Streamlined Workflows: IMS software streamlines inventory-related processes, from receiving goods to order fulfillment, reducing bottlenecks and improving overall operational flow.

- Increased Employee Productivity: With automated processes and readily available information, employees can work more efficiently, handle larger volumes of work, and reduce errors, boosting overall productivity.

- Time Savings: Automation and streamlined processes translate directly into significant time savings across inventory operations, allowing businesses to process orders faster, manage stock more effectively, and respond quickly to customer needs.

Reduced Costs and Increased Profitability

- Minimize Holding Costs: Overstocking ties up valuable capital and incurs storage costs, insurance, and the risk of obsolescence. An IMS helps optimize stock levels, minimizing holding costs and freeing up capital for other investments.

- Prevent Stockouts and Lost Sales: Stockouts lead to lost sales, dissatisfied customers, and potential damage to your brand reputation. IMS systems provide alerts and forecasting tools to prevent stockouts and ensure you can always meet customer demand.

- Optimize Ordering Processes: IMS software can analyze sales data and demand patterns to recommend optimal order quantities and reorder points, ensuring you order the right amount of stock at the right time, securing better pricing and reducing rush orders.

- Reduce Inventory Loss and Waste: By tracking inventory accurately and implementing FIFO (First-In, First-Out) methods, businesses can minimize spoilage, damage, and obsolescence, especially crucial for industries dealing with perishable goods.

- Negotiate Better Vendor Terms: With accurate data on purchasing history and vendor performance, businesses can negotiate better pricing and payment terms with suppliers, improving profitability.

Improved Accuracy and Visibility

- Real-Time Inventory Data: IMS systems provide up-to-the-minute visibility into stock levels across all locations, ensuring you always know exactly what you have in stock, where it is, and its value.

- Reduced Data Entry Errors: Automated data capture through barcode scanning and system integrations minimizes manual data entry, significantly reducing errors and improving data accuracy.

- Enhanced Forecasting Accuracy: By analyzing historical sales data and trends, IMS software provides more accurate demand forecasts, enabling better inventory planning and reducing the risk of overstocking or stockouts.

- Improved Reporting and Analysis: IMS systems generate comprehensive reports on key inventory metrics, providing valuable insights into performance, trends, and areas for improvement, supporting data-driven decision-making.

Optimized Warehouse Operations

- Efficient Space Management: IMS software can help optimize warehouse layout and storage strategies, ensuring efficient use of space and reducing storage costs.

- Streamlined Picking and Packing: IMS-integrated picking and packing processes, often guided by barcode scanning, minimize errors, speed up order fulfillment, and improve warehouse efficiency.

- Improved Warehouse Workflows: By automating tasks and providing clear instructions, IMS systems streamline warehouse workflows, reducing bottlenecks and improving overall operational efficiency.

Better Decision Making and Forecasting

- Data-Driven Insights: IMS systems provide a wealth of data on inventory levels, sales trends, customer demand, and vendor performance, empowering businesses to make informed decisions based on real-time insights rather than guesswork.

- Trend Analysis and Predictive Analytics: Advanced IMS features can analyze historical data to identify trends, predict future demand, and optimize inventory strategies proactively.

- Informed Purchasing Decisions: With accurate data on stock levels, sales forecasts, and lead times, businesses can make informed purchasing decisions, avoiding overstocking or stockouts and securing the best possible prices.

Enhanced Customer Satisfaction

- Timely Order Fulfillment: Efficient inventory management ensures products are readily available, enabling faster order processing and delivery, leading to improved customer satisfaction.

- Reduced Order Delays and Errors: Accurate inventory data and streamlined processes minimize order delays and picking errors, ensuring customers receive the right products on time, every time.

- Improved Customer Service: With real-time inventory visibility, customer service representatives can provide accurate information about product availability and order status, enhancing customer experience.

By realizing these tangible benefits, businesses in Dubai and the UAE can leverage Inventory Management Systems to transform their operations, gain a competitive edge, and achieve sustainable success in today’s demanding marketplace. ![]()

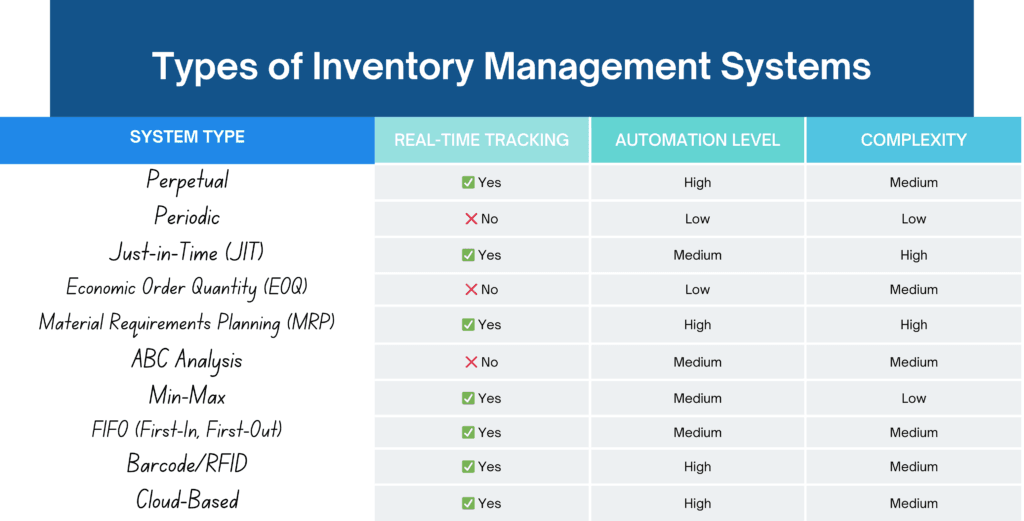

Exploring the ‘How’: Types of Inventory Management Systems

Choosing the right Inventory Management System is crucial, and the best option depends heavily on your specific business needs, industry, size, and complexity of operations in Dubai and the UAE. There’s no one-size-fits-all solution. Let’s explore the common types of inventory management systems:

Perpetual Inventory System

- Description: Provides real-time, continuous tracking of inventory levels. Every time a sale or purchase occurs, the system instantly updates stock quantities.

- Key Features: Real-time data, automated updates, continuous monitoring, detailed transaction history.

- Best Suited For: Businesses requiring precise, up-to-the-minute inventory visibility, such as e-commerce, retail, and businesses with high transaction volumes.

- Example: A supermarket in Dubai using barcode scanners at checkout to automatically update inventory levels as items are sold.

Periodic Inventory System

- Description: Inventory is physically counted at fixed intervals (e.g., weekly, monthly). Stock levels are updated only after these periodic counts.

- Key Features: Manual process, physical stocktaking, updates at intervals, simpler to implement initially.

- Best Suited For: Small businesses with limited inventory and lower transaction volumes, where real-time accuracy is less critical.

- Example: A small retail store in Sharjah conducting a manual stock count at the end of each week to update inventory records.

Just-in-Time (JIT) Inventory System

- Description: Aims to minimize inventory holding by receiving goods only when they are needed for production or sale. Relies heavily on accurate demand forecasting and efficient supply chains.

- Key Features: Minimize stock, demand-driven, efficient for manufacturing, reduces holding costs, requires strong supplier relationships.

- Best Suited For: Manufacturing companies and businesses with predictable demand and reliable suppliers, often used in automotive and electronics industries.

- Example: A car manufacturer in Jebel Ali receiving components from suppliers just in time for assembly on the production line.

Economic Order Quantity (EOQ)

- Description: A formula-based approach to determine the optimal order quantity that minimizes total inventory costs, considering ordering costs and holding costs.

- Key Features: Formula-driven, cost minimization, optimal order quantity calculation, considers ordering and holding costs.

- Best Suited For: Businesses with relatively stable demand and predictable ordering and holding costs, useful for optimizing purchasing decisions.

- Example: A wholesale distributor in Dubai using EOQ to calculate the most cost-effective quantity of goods to order from suppliers.

Material Requirements Planning (MRP)

- Description: A software-driven system used primarily in manufacturing to plan and manage production and inventory based on forecasted demand and bill of materials.

- Key Features: Production planning, software-driven, complex manufacturing, bill of materials, demand forecasting, production scheduling.

- Best Suited For: Manufacturing companies with complex production processes, multiple components, and fluctuating demand, common in industries like aerospace and machinery.

- Example: A manufacturing plant in Abu Dhabi using MRP to plan the production of complex machinery, ensuring all necessary components are available at the right time.

ABC Analysis

- Description: Categorizes inventory items into three categories (A, B, C) based on their value and importance. ‘A’ items are high-value, ‘B’ are medium-value, and ‘C’ are low-value. Management efforts are prioritized based on category.

- Key Features: Categorization by value, prioritized management, resource allocation, focuses on high-value items.

- Best Suited For: Businesses with a wide range of inventory items with varying values, allowing for focused management of critical items.

- Example: A retail store in Dubai using ABC analysis to prioritize inventory management efforts on high-value items like electronics (A items) compared to lower-value items like stationery (C items).

Minimum-Maximum Inventory Control System

- Description: Sets predefined minimum and maximum stock levels for each item. When stock falls below the minimum level, a reorder is triggered to bring it back up to the maximum level.

- Key Features: Predefined levels, automated reordering (often), simple to implement, helps maintain stock within desired ranges.

- Best Suited For: Businesses seeking to maintain consistent stock levels and automate reordering for frequently used items.

- Example: A restaurant in Dubai using a min-max system to ensure they always have sufficient quantities of key ingredients like flour and sugar.

First-In, First-Out (FIFO)

- Description: Ensures that the oldest inventory items are sold or used first. Crucial for perishable goods and items with expiry dates to prevent spoilage and obsolescence.

- Key Features: Oldest stock sold first, perishable goods, prevents obsolescence, reduces waste, important for food, pharmaceuticals, and fashion industries.

- Best Suited For: Businesses dealing with perishable goods, fashion items with seasonal trends, or products with expiry dates.

- Example: A supermarket in Dubai implementing FIFO for its dairy and fresh produce sections to ensure freshness and minimize waste.

Barcode and RFID Systems

- Description: Utilize barcode or Radio-Frequency Identification (RFID) technology for automated inventory tracking. Scanners and readers capture data quickly and accurately, improving efficiency and reducing errors.

- Key Features: Automated tracking, scanning, data accuracy, efficiency, reduced manual effort, improved speed.

- Best Suited For: Businesses seeking to improve data accuracy, speed up inventory processes, and reduce manual labor, beneficial for warehouses, retail, and manufacturing.

- Example: A large distribution center in Jebel Ali using RFID tags to track pallets and cartons as they move through the warehouse, improving receiving, putaway, and shipping processes.

Cloud-Based Inventory Management Systems

- Description: Software hosted on remote servers and accessed via the internet. Offers accessibility from anywhere, scalability, real-time data synchronization, and often subscription-based pricing.

- Key Features: Accessibility, scalability, real-time data, remote access, subscription model, often integrates with other cloud-based business applications.

- Best Suited For: Businesses of all sizes, especially those with multiple locations, remote teams, or a need for scalable and accessible solutions. Popular in Dubai and UAE due to its flexibility and cost-effectiveness.

- Example: An e-commerce business in Dubai using a cloud-based IMS to manage inventory across its online store and physical warehouse, accessible to staff from different locations.

Understanding these diverse types of inventory management systems is the first step in selecting the right solution for your business in Dubai and the UAE. The next step is to consider the essential features that will truly make a difference to your operations.

Key Features to Look for in an Inventory Management System

When selecting an Inventory Management System for your business in Dubai or the UAE, focusing on essential features is crucial to ensure it truly addresses your specific needs and delivers tangible benefits. Here are the key features to prioritize: Consider how a platform like Microsoft Dynamics 365 Business Central encompasses many of these critical features within its comprehensive suite.

Inventory Tracking and Visibility

- Real-Time Stock Updates: The system should provide up-to-the-minute visibility into stock levels across all locations, reflecting every transaction instantly.

- Stock Level Monitoring: Easy-to-view dashboards and reports showing current stock levels for all items, including on-hand, committed, and available quantities.

- Location Tracking: Ability to track inventory across multiple warehouses, storage locations, or even within different zones within a warehouse.

- Item History Tracking: Detailed records of all inventory movements, including receipts, shipments, adjustments, and transfers, providing a complete audit trail.

Barcode Scanning and RFID Integration

- Barcode/RFID Compatibility: Seamless integration with barcode scanners and RFID readers for fast and accurate data capture during receiving, picking, packing, and stocktaking.

- Automated Data Capture: Minimize manual data entry by automatically capturing inventory data through scanning, reducing errors and improving efficiency.

- Mobile Scanning Capabilities: Support for mobile devices and apps for inventory management tasks on the go, enhancing flexibility and accessibility for warehouse staff.

Purchase Order Management

- Purchase Order Creation: Streamlined process for creating and sending purchase orders to vendors directly from the system.

- Vendor Management: Centralized vendor database with contact information, pricing history, and performance tracking.

- PO Tracking and Status Updates: Real-time tracking of purchase order status, from creation to receipt, ensuring visibility into the procurement pipeline.

- Invoice Management: Integration with invoicing processes for efficient reconciliation of purchase orders and vendor invoices.

Multi-Location Inventory Management

- Warehouse Management: Features to manage multiple warehouses or storage locations effectively, tracking inventory separately for each location.

- Inter-Warehouse Transfers: Streamlined processes for transferring stock between warehouses, with accurate tracking of movements and quantity adjustments.

- Consolidated Inventory View: Ability to view a consolidated inventory picture across all locations, providing a holistic overview of total stock.

Product Details and Item Management

- Detailed Product Descriptions: Fields to store comprehensive product information, including descriptions, specifications, images, and dimensions.

- SKU and Barcode Management: Support for generating and managing Stock Keeping Units (SKUs) and barcodes for unique product identification.

- Supplier Information: Ability to link products to specific suppliers, track supplier pricing, and manage lead times.

- Variant Management: Features to manage product variations (e.g., size, color) and track inventory for each variant separately.

- Pricing and Cost Management: Fields to store wholesale and retail prices, track inventory costs, and calculate profit margins.

- Product Categorization: Ability to categorize products for better organization, reporting, and analysis (e.g., by product type, brand, or category).

Inventory Reporting and Analytics

- Stock Reports: Real-time reports on current stock levels, low stock items, stock valuation, and inventory aging.

- Sales Data Analysis: Reports analyzing sales trends, product performance, and customer demand patterns to inform inventory planning.

- Inventory Turnover Reports: Metrics to track how quickly inventory is sold and replenished, indicating efficiency and potential areas for improvement.

- Customizable Reports: Flexibility to create custom reports based on specific data requirements and KPIs.

- Data Export and Integration: Ability to export data in various formats (e.g., CSV, Excel) for further analysis and integration with other business intelligence tools.

Inventory Optimization and Forecasting

- Demand Forecasting Tools: Features to analyze historical sales data and predict future demand, helping optimize stock levels and prevent stockouts.

- Reorder Point Calculation: Automated calculation of reorder points based on demand forecasts, lead times, and safety stock levels, triggering timely reordering.

- Inventory Optimization Recommendations: System-generated recommendations for optimal stock levels, order quantities, and safety stock adjustments.

Integration Capabilities

- CRM Integration: Integration with Customer Relationship Management (CRM) systems to link inventory data with customer information and sales activities.

- POS Integration: Integration with Point of Sale (POS) systems for seamless updates of inventory levels upon sales transactions in retail environments.

- Accounting Software Integration: Integration with accounting software to synchronize financial data related to inventory, purchases, and sales.

- E-commerce Platform Integration: Integration with e-commerce platforms to manage inventory for online stores, automatically updating stock levels and fulfilling online orders. Solutions like Microsoft Dynamics 365 Business Central are designed with robust integration capabilities in mind.

User-Friendly Interface and Accessibility

- Intuitive User Interface: Easy-to-navigate and user-friendly interface, minimizing training time and ensuring user adoption.

- Cloud Access and Mobile Apps: Cloud-based accessibility from anywhere with an internet connection, and dedicated mobile apps for on-the-go inventory management.

- User Roles and Permissions: Ability to define user roles and permissions to control access to sensitive inventory data and functionalities.

Alerts and Notifications

- Low Stock Alerts: Automated alerts when stock levels fall below predefined reorder points, prompting timely replenishment.

- Reorder Reminders: Notifications reminding users to create purchase orders for items nearing their reorder points.

- Expiry Tracking and Alerts: For perishable goods, alerts for items nearing their expiry dates, enabling proactive management and minimizing waste.

By carefully evaluating these key features and aligning them with your specific business requirements in Dubai and the UAE, you can select an Inventory Management System that will truly empower your operations and drive significant improvements.

Navigating the Labyrinth: Challenges in Inventory Management (and How to Overcome Them)

Even with the best intentions and systems in place, inventory management is not without its challenges. Businesses in Dubai and the UAE face unique hurdles and understanding these common pitfalls and how to overcome them is crucial for success. Implementing a comprehensive system like Microsoft Dynamics 365 Business Central can help mitigate many of these challenges through its integrated features and functionalities

Inaccurate Data and Manual Errors

- The Challenge: Relying on manual data entry, spreadsheets, and periodic stock counts is prone to human error. Inaccurate data leads to poor decision-making, stock discrepancies, and inefficiencies.

- The Solution: Implement an Inventory Management System with automated data capture through barcode scanning or RFID. Integrate the IMS with POS and accounting systems to ensure data consistency across platforms. Conduct regular cycle counts to verify system data against physical stock and identify discrepancies promptly.

Demand Fluctuations and Forecasting Difficulties

- The Challenge: Dubai and the UAE markets can be subject to seasonal demand fluctuations, promotional events, and unpredictable market trends. Inaccurate demand forecasts lead to either overstocking or stockouts.

- The Solution: Utilize IMS features for demand forecasting, leveraging historical sales data, trend analysis, and even external factors like seasonality and marketing campaigns. Implement flexible inventory strategies that can adapt to changing demand patterns. Consider safety stock levels to buffer against unexpected demand surges.

Warehouse Inefficiency and Space Management

- The Challenge: Poor warehouse layout, disorganized storage, and inefficient picking/packing processes lead to wasted space, increased labor costs, and slower order fulfillment.

- The Solution: Optimize warehouse layout based on product velocity and storage requirements. Implement efficient putaway and picking strategies, guided by the IMS. Consider using warehouse management system (WMS) features within the IMS to further streamline warehouse operations. Utilize vertical storage and space-saving techniques to maximize warehouse capacity.

Supply Chain Complexity and Disruptions

- The Challenge: Global supply chains, long lead times, and potential disruptions (e.g., shipping delays, geopolitical events) can impact inventory availability and planning.

- The Solution: Maintain strong relationships with multiple suppliers to diversify supply sources and mitigate risks. Implement robust supplier management features within the IMS to track vendor performance and lead times. Utilize safety stock and buffer inventory to account for potential supply chain disruptions. Improve communication and collaboration with suppliers for better visibility and coordination.

Overstocking and Stockouts

- The Challenge: Finding the right balance between having enough inventory to meet demand and avoiding excess stock that ties up capital is a constant struggle. Overstocking increases holding costs, while stockouts lead to lost sales and customer dissatisfaction.

- The Solution: Implement demand forecasting and reorder point calculations within the IMS to optimize stock levels. Regularly analyze inventory turnover rates to identify slow-moving items and adjust ordering strategies. Utilize ABC analysis to prioritize management efforts on high-value items and optimize stock levels accordingly.

Inventory Loss and Damage

- The Challenge: Inventory can be lost due to theft, damage, spoilage (especially for perishable goods), or simply going missing. These losses directly impact profitability.

- The Solution: Implement robust security measures in warehouses and storage areas. Track inventory movements meticulously within the IMS to identify and investigate discrepancies. Implement FIFO and expiry tracking for perishable goods to minimize spoilage. Train staff on proper handling and storage procedures to reduce damage. Conduct regular stock audits and cycle counts to identify and address losses promptly.

By proactively addressing these common challenges and implementing the recommended solutions, businesses in Dubai and the UAE can navigate the complexities of inventory management and unlock its full potential.

Best Practices for Effective Inventory Management in Dubai & UAE

To truly excel at inventory management in Dubai and the UAE, adopting best practices is essential. These practices, combined with the right Inventory Management System, will help you optimize your operations and achieve superior results: Consider how a system like Microsoft Dynamics 365 Business Central can facilitate the implementation of these best practices.

Regular Inventory Audits and Cycle Counting

- Practice: Conduct regular physical stock audits to verify the accuracy of system data and identify discrepancies. Implement cycle counting, a process of counting a small portion of inventory daily or weekly, rather than a full physical count.

- Benefit: Ensures data accuracy, identifies discrepancies promptly, allows for corrective actions, and maintains reliable inventory records.

Implement FIFO and Expiry Tracking

- Practice: Strictly adhere to the First-In, First-Out (FIFO) method, especially for perishable goods. Implement expiry date tracking within the IMS and use alerts to manage expiring stock.

- Benefit: Minimizes spoilage and waste, ensures product freshness, reduces obsolescence, and complies with regulatory requirements (especially for food and pharmaceuticals).

Optimize Warehouse Layout and Processes

- Practice: Design warehouse layout for efficient product flow, considering product velocity and storage requirements. Implement optimized putaway and picking strategies, guided by the IMS. Streamline receiving and shipping processes.

- Benefit: Maximizes space utilization, reduces travel time for warehouse staff, speeds up order fulfillment, and improves overall warehouse efficiency.

Leverage Technology and Automation

- Practice: Implement a robust Inventory Management System with barcode scanning or RFID integration. Automate routine tasks such as data entry, reordering, and reporting. Explore warehouse automation technologies where appropriate.

- Benefit: Reduces manual effort, minimizes errors, improves data accuracy, increases efficiency, and frees up staff for strategic tasks.

Demand Forecasting and Planning

- Practice: Utilize IMS features for demand forecasting, leveraging historical data and trend analysis. Regularly review and adjust forecasts based on market changes and promotional plans.

- Benefit: Optimizes stock levels, prevents overstocking and stockouts, improves purchasing decisions, and ensures you can meet customer demand effectively.

Maintain Strong Vendor Relationships

- Practice: Build strong, collaborative relationships with key vendors. Communicate openly and regularly regarding demand forecasts and order plans. Track vendor performance and lead times.

- Benefit: Ensures reliable supply chains, improves communication and coordination, facilitates better negotiation of pricing and terms, and mitigates supply chain risks.

Employee Training and Process Standardization

- Practice: Provide comprehensive training to all staff involved in inventory management on IMS usage, processes, and best practices. Standardize inventory procedures and workflows across all locations and departments.

- Benefit: Ensures consistent application of best practices, reduces errors due to lack of knowledge, improves efficiency, and enhances overall team performance.

By consistently applying these best practices, businesses in Dubai and the UAE can elevate their inventory management capabilities, achieve operational excellence, and gain a significant competitive advantage.

The Future is Now: Inventory Management Trends in 2025 and Beyond

The field of inventory management is constantly evolving, driven by technological advancements and changing business demands. As we look towards 2025 and beyond, several key trends are poised to reshape inventory management in Dubai, the UAE, and globally: Solutions like Microsoft Dynamics 365 Business Central are actively incorporating these emerging technologies to provide cutting-edge inventory management capabilities.

AI and Machine Learning in Inventory Management

- Trend: Artificial Intelligence (AI) and Machine Learning (ML) are being increasingly integrated into IMS to enhance predictive analytics, demand forecasting, and automation.

- Impact: AI-powered systems can analyze vast datasets to identify complex demand patterns, improve forecasting accuracy, optimize stock levels dynamically, and automate decision-making in inventory management.

- Example: IMS using ML algorithms to predict demand fluctuations based on historical data, seasonality, promotions, and even external factors like weather patterns or social media trends.

Cloud-Based and Mobile-First Solutions

- Trend: Cloud-based IMS solutions are becoming the norm, offering greater accessibility, scalability, and real-time data synchronization. Mobile-first design ensures accessibility and usability on smartphones and tablets.

- Impact: Businesses gain flexibility to manage inventory from anywhere, real-time data access for all stakeholders, and easier scalability to adapt to growth. Mobile apps empower warehouse staff to perform tasks on the go, improving efficiency.

- Example: A multi-location retail chain in Dubai using a cloud-based IMS accessible to store managers, warehouse staff, and headquarters, with mobile apps for stocktaking and order management.

Internet of Things (IoT) and Sensor Integration

- Trend: Integration of IoT sensors and devices into inventory management for real-time tracking, condition monitoring, and automated data updates.

- Impact: Real-time visibility into inventory location, temperature, humidity, and other environmental conditions (crucial for perishable goods). Automated stock level updates based on sensor data, reducing manual counts. Improved asset tracking and security.

- Example: A pharmaceutical distributor in the UAE using IoT sensors to monitor temperature and humidity conditions in their warehouses, ensuring the integrity of temperature-sensitive medications and receiving automated alerts for any deviations.

Automation and Robotics in Warehousing

- Trend: Increased adoption of automation and robotics in warehouses for tasks like picking, packing, sorting, and material handling.

- Impact: Significant improvements in warehouse efficiency, speed, and accuracy. Reduced labor costs and improved throughput. Optimized space utilization and faster order fulfillment.

- Example: An e-commerce fulfillment center in Dubai using robots for automated picking and packing of orders, significantly speeding up order processing and reducing errors.

Blockchain for Supply Chain Transparency

- Trend: Exploring the use of blockchain technology to enhance supply chain transparency, traceability, and security in inventory management.

- Impact: Improved product traceability throughout the supply chain, enhanced security and authenticity verification, reduced counterfeiting, and increased trust among stakeholders.

- Example: A luxury goods retailer in Dubai using blockchain to track the provenance of their products, ensuring authenticity and providing customers with transparent supply chain information.

Sustainability and Green Inventory Management

- Trend: Growing focus on sustainability and environmentally conscious practices in inventory management, aiming to reduce waste, optimize resource utilization, and promote circular economy principles.

- Impact: Reduced waste through better demand forecasting and inventory optimization. Optimized packaging and shipping practices to minimize environmental impact. Increased focus on reverse logistics and product lifecycle management.

- Example: A fashion retailer in Dubai implementing inventory management strategies to reduce textile waste, optimize packaging, and promote clothing recycling programs.

These trends indicate a future of inventory management that is more intelligent, automated, connected, and sustainable. Businesses in Dubai and the UAE that embrace these trends will be best positioned to thrive in the evolving marketplace.

Inventory Management in Dubai & UAE: Specific Considerations

While the general principles of inventory management apply globally, businesses operating in Dubai and the UAE face a unique set of considerations that require tailored approaches:

Unique Challenges and Opportunities in the UAE Market

- Rapid Growth and Dynamic Market: The UAE economy, particularly Dubai, is characterized by rapid growth, dynamic market conditions, and evolving consumer preferences. Inventory management systems need to be agile and adaptable to these changes.

- Diverse Industries: From tourism and retail to logistics and manufacturing, the UAE economy encompasses a wide range of industries with diverse inventory management needs. Solutions must be industry-specific or highly customizable.

- Logistics Hub and Re-export Trade: Dubai and the UAE are major logistics hubs and centers for re-export trade. Inventory management systems must handle complex supply chains, international shipping, and customs regulations.

- Multicultural Workforce: Businesses in the UAE often have multicultural workforces, requiring IMS solutions to be user-friendly and potentially multilingual to ensure effective adoption across teams.

- Focus on Innovation and Technology: The UAE government strongly promotes innovation and technology adoption. Businesses are expected to embrace digital solutions like advanced inventory management systems.

Adapting Inventory Management to the Dubai & UAE Business Environment

- Regulatory Compliance: Be aware of UAE regulations related to inventory, import/export, customs, and specific industry requirements (e.g., food safety, pharmaceuticals). Ensure your IMS helps you comply with these regulations.

- Cultural Nuances: Consider cultural factors in business practices and communication when dealing with suppliers, customers, and employees in the UAE. Choose an IMS vendor that understands the local business culture.

- Market Demands and Consumer Preferences: Stay attuned to local market trends, consumer preferences, and seasonal demand patterns in the UAE. Adapt your inventory strategies accordingly.

- Scalability and Flexibility: Choose an IMS that can scale with your business growth in the rapidly expanding UAE market. Opt for flexible solutions that can be customized to your evolving needs.

Finding the Right Inventory Management System in Dubai & UAE

- Local Vendors and Support: Consider local IMS vendors in Dubai or the UAE who understand the local market and can provide on-site support and training in Arabic and English.

- Customization and Industry-Specific Solutions: Look for IMS solutions that can be customized to your specific industry needs and business processes in the UAE market. Microsoft Dynamics 365 Business Central, for example, offers various modules and customization options to suit different industries.

- Integration with Local Systems: Ensure the IMS can integrate with other business systems commonly used in the UAE, such as local accounting software or e-commerce platforms.

- Cloud-Based Accessibility: Prioritize cloud-based solutions for accessibility, scalability, and remote management, especially beneficial for businesses with multiple locations in the UAE.

By considering these specific factors, businesses in Dubai and the UAE can select and implement inventory management systems that are truly tailored to their unique operating environment and maximize their chances of success.

Conclusion: Take Control of Your Inventory, Drive Business Success

Mastering inventory management is no longer a choice, but a necessity for businesses seeking to thrive in the competitive landscape of Dubai and the UAE. A robust Inventory Management System is not just software; it’s a strategic investment that empowers you to take control of your operations, optimize costs, enhance customer satisfaction, and drive sustainable business success. For many businesses aiming for a comprehensive and integrated solution, Microsoft Dynamics 365 Business Central stands out as a powerful option.

Recap of Key Benefits and Importance of IMS

Let’s reiterate the transformative power of a well-implemented IMS:

- Unleashes Efficiency: Automates tasks, streamlines workflows, and boosts productivity across inventory operations.

- Optimizes Profitability: Reduces holding costs, prevents stockouts, optimizes ordering, and minimizes waste, directly impacting your bottom line.

- Ensures Accuracy and Visibility: Provides real-time data, reduces errors, and offers comprehensive reporting for informed decision-making.

- Enhances Customer Experience: Enables timely order fulfillment, reduces delays, and improves customer service, fostering loyalty and positive brand perception.

- Provides a Competitive Edge: Allows you to respond quickly to market changes, operate more efficiently, and offer superior service compared to competitors.

Explore and implement an IMS for Your Business

If you’re ready to elevate your business operations in Dubai or the UAE, now is the time to explore and implement an Inventory Management System. Take the first step towards transforming your inventory from a potential liability into a powerful asset.

- Assess your needs: Carefully evaluate your current inventory processes, challenges, and specific requirements.

- Research IMS solutions: Explore different types of IMS and identify systems that align with your business size, industry, and budget. Consider exploring the capabilities of Microsoft Dynamics 365 Business Central as part of your research.

- Request demos and trials: Test drive shortlisted IMS solutions to evaluate their user-friendliness, features, and suitability for your team.

- Choose a reputable vendor: Select a vendor with experience in the UAE market, offering reliable support, training, and customization options.

- Plan for implementation: Develop a clear implementation plan, involving your team and ensuring proper data migration and training.

Final Thought: Embrace the Future of Inventory Management

As technology continues to advance, the future of inventory management is bright. Embrace the trends of AI, cloud, IoT, and automation to stay ahead of the curve. Continuous improvement and adaptation are key to maintaining a competitive edge in the ever-evolving business landscape of Dubai and the UAE. By investing in a robust Inventory Management System and adopting best practices, you’ll not only manage your inventory effectively but also lay the foundation for long-term business growth and prosperity.

Square International Technology Consulting DMCC

Regd. Office:

Office No 1408, Tiffany Towers, Cluster W, Jumeirah Lake Towers, Dubai, United Arab Emirates